Accelerate Innovation: Rapid Prototyping for Fishing Tackle

Bring your next fishing tackle concept to life faster than ever. Maple Forge Tackle offers precision rapid prototyping services tailored for manufacturers, inventors, and product developers in the angling industry.

Start Your Prototype Project TodayAdvanced Rapid Prototyping Services

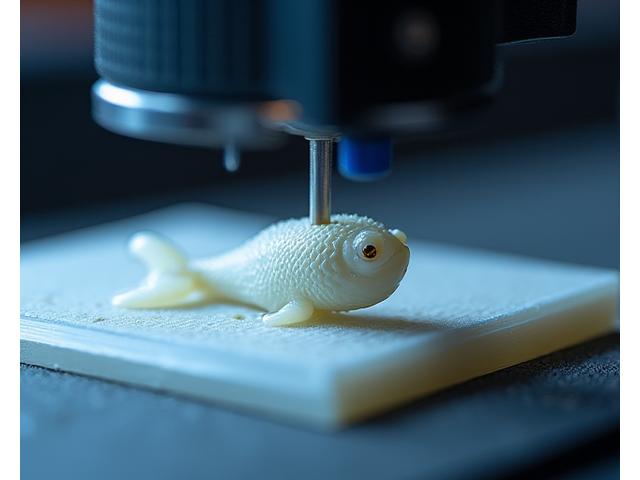

Cutting-Edge Fabrication

Leveraging state-of-the-art 3D printing, advanced CNC machining, and traditional metal forging, we create functional and aesthetic prototypes with unparalleled accuracy and detail. From intricate lure designs to robust reel components, our methods ensure your vision is realized.

Functional & Aesthetic Materials

We work with a wide range of materials, including high-strength polymers, aluminum, brass, and stainless steel, to perfectly match the functional and aesthetic demands of your fishing tackle. We help you choose the ideal material for durability, weight, and performance.

Concept to Production Support

Our prototyping process is designed with your end goal in mind. We provide scaling capabilities, ensuring your validated prototype can transition smoothly from a single unit to full-scale production. We integrate with your existing design workflows for maximum efficiency.

Unparalleled Fishing Industry Expertise

At Maple Forge Tackle, we don't just understand metal; we understand angling. Our team brings decades of combined experience in custom tackle design, manufacturing, and actual fishing.

- Deep understanding of tackle design requirements for various techniques.

- Extensive experience with fishing-specific materials, coatings, and finishes.

- In-depth knowledge of angling applications and critical performance needs.

- Collaborative approach with leading industry professionals and independent inventors, fostering tackle innovation in Kingston and beyond.

Our Streamlined Development Process

1. Concept & Feasibility

Initial consultation to understand your vision, assess feasibility, and define project scope. We provide expert input to refine your initial ideas.

2. Design & Optimization

Collaborative design refinement, leveraging our metalwork and fishing expertise. We offer recommendations for optimization in material, form, and function.

3. Prototyping & Iteration

Rapid fabrication of prototypes using chosen methods. We facilitate iterative improvements based on initial testing and your feedback.

4. Validation & Production

Thorough testing and validation to ensure design specifications are met. We then assist with production planning for seamless manufacturing scalability.

Rigorous Prototype Testing and Validation

A prototype is only as good as its performance. We offer comprehensive testing services to validate your fishing gear prototypes, ensuring they stand up to the challenge of real-world angling conditions.

- Functional testing of mechanics, movement, and durability against intended use.

- Performance validation against your precise design specifications and industry benchmarks.

- Coordination of field testing with experienced local anglers and professional guides for unparalleled real-world feedback.

- Actionable recommendations for iterative improvements, ensuring your prototype is production-ready.

Your Vision, Our Confidentiality: Intellectual Property Protection

We respect the critical importance of your intellectual property. Maple Forge Tackle operates with stringent security and confidentiality protocols to safeguard your innovative designs.

- **Non-Disclosure Agreements (NDAs):** Standard practice for every project, protecting your innovations from day one.

- **Secure Facility & Access Controls:** Our workshop is secured to prevent unauthorized access to sensitive project information and prototypes.

- **Confidential Project Management:** Your project details are handled with the utmost discretion by a dedicated team.

- **Patent Consideration Support:** While we are not legal counsel, we can guide you on documentation that aids in patent applications.

Proven Innovation: Our Prototype Success Stories

"Maple Forge Tackle turned our complex jig design into a functional, field-ready prototype in record time. Their material recommendations were spot-on, dramatically improving lure action. It's now one of our best-sellers."

"As an independent inventor, trust and precision are everything. Maple Forge helped me refine my conceptual hook design into multiple functional prototypes that have already garnered significant investor interest. Their confidentiality was paramount."